This article explains how to choose the right rubber tracks for various mini excavators.

You will learn that:

- The right track improves ride quality, traction, and fuel efficiency.

- It’s important to know the old track’s width, pitch, and number of teeth.

- There are five classification types often found in rubber track product numbers.

- It’s wise to replace sprockets when replacing rubber tracks too.

Why choosing the right rubber track matters

Selecting the right rubber track significantly improves a mini excavator’s performance. Properly fitted tracks result in better ride quality, increased traction, reduced fuel consumption, and extended equipment lifespan. Using an incorrect track can lead to faster wear, costly breakdowns, and unnecessary downtime.

3 steps to identify the right rubber track

Follow these steps to ensure you select the correct rubber track:

Step 1: Find your machine’s brand and model

Check the brand and model on your machine’s nameplate. You can then use the Kramp’s Model Search tool to quickly find your machine and its compatible tracks.

Step 2: Measure your rubber track correctly

But what if the mini excavator you’re looking for is not listed? Or perhaps the track size isn’t stamped inside your existing track? Then you’ll need to measure it manually:

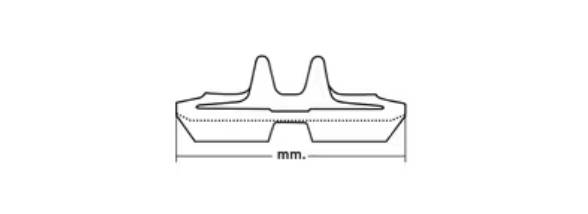

Width: Measure the track width in millimetres.

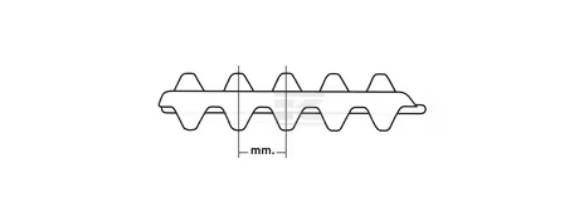

Pitch: Measure from the centre of one drive lug to the centre of the next lug.

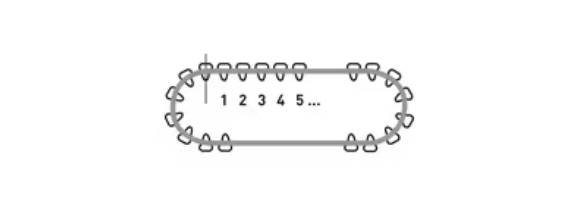

Links: Count the total number of teeth (or links) around the inner circumference of the track.

Knowing these measurements will help you narrow down your search for the best track.

Step 3: Understanding track classifications

Beyond these basic measurements, rubber tracks have classifications that can be found in their product ID numbers. These classifications vary depending on the manufacturer and model type.

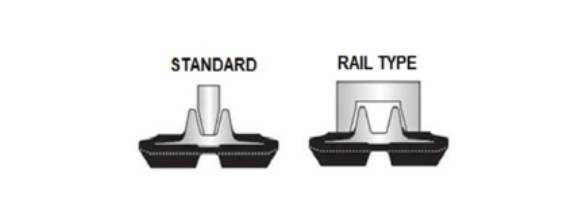

- “K” refers to a rail-type guidance system, where the tracks run on a reinforced rail surface instead of on the links. This design ensures proper alignment and smooth movement. If the tracks do not have a “K,” they use a standard guidance system.

- “Y” is only used for tracks compatible with Yanmar machines.

- “N” or “A” indicates narrow sprocket guidance.

- “W” or “B” indicates wide sprocket guidance.

- “Asymmetric” tells you that these tracks have offset links.

By understanding these letters, you are more likely to find a rubber track that fits perfectly and performs as intended.

A common mistake: sprockets and rollers

Not everyone knows this. But if it’s time to replace a machine’s rubber tracks, it’s also good to replace its sprockets.

Why? Because new tracks paired with old sprockets often fit poorly and wear quicker than they should. Signs of worn sprockets include sharp or pointed teeth, uneven wear, and visible metal fatigue. On top of that, the upper or lower rollers might be worn, causing them to make unusual noises, show visible cracks, or spin irregularly.

It’s also important to check the condition of the final drive, check oil levels and change the oil when needed. Finally, proper track tension is critical to prevent it from slipping or de-tracking (meaning the track will run off the machine).

How to choose between rubber track brands

Once you know what you are looking for, Kramp offers aftermarket rubber track options for many brands of mini excavators.

Kramp rubber tracks deliver dependable quality at a competitive price point, ensuring strong performance without overspending.

We are here to help

If you’re still stuck choosing the right rubber track, get in touch with a Kramp expert.

Otherwise, click below to start your search for rubber tracks by machine model.