O-rings are mainly used as static seals. Different aspects play a role when choosing an o-ring. That is why we want to help you make the right choice. You can read our advice on choosing the right o-ring here.

What are o-rings?

An o-ring is a ring-shaped seal with a round cross-section. O-rings are among the most commonly used seals and are mainly used as static seals for various liquids and gases. They are simple to produce, reliable and easy to install. The material from which o-rings are made is mainly an elastomer (NBR rubber), but we also know o-rings that are manufactured from other materials such as PTFE. The choice depends, among other things, on the type of medium to be sealed and under what temperatures the o-ring will be used.

Areas of application of o-rings are;

- Static axial (flange seal)

- Static radial (shaft seal)

- Dynamic

- Linear (piston/rod seal)

- Rotary (shaft seal)

- Oscillating (shaft seal)

What is important to know when choosing o-rings?

O-rings are available in various shapes and sizes. Proper seal design begins with careful consideration of the application. For example, the material hardness is determined by the friction and pressure to which the seal is exposed. The cross-section of the seal also plays an important role. When picking the correct o-ring for an application, the first thing that is important is to find the most suitable solution. This not only ensures a good seal, but also prevents any leakage and other damage. What else is important when choosing the right o-ring?

Our tips

When purchasing o-rings as seals, it is important to take the following points into account:

- What liquid(s) or gas(es) will the o-ring be sealing?

- What other fluids can the o-ring come into contact with? Consider detergents, for instance.

- The degree to which the o-ring must be resistant to high and/or low temperatures.

- The correct size of the o-ring. If the o-ring is too large or too small, it may cause damage. The correct size of the o-ring is determined by the internal diameter of the ring and the diameter of the thread.

- What operating pressures are we dealing with?

- The o-ring can be used for static applications up to 50 bar. At higher pressures, the o-rings should be used in combination with backup rings.

- The o-ring can be used for dynamic applications up to 50 bar.

Difference between the o-ring and the x-ring

Difference between the o-ring and the x-ringHow is the size of the o-ring determined?

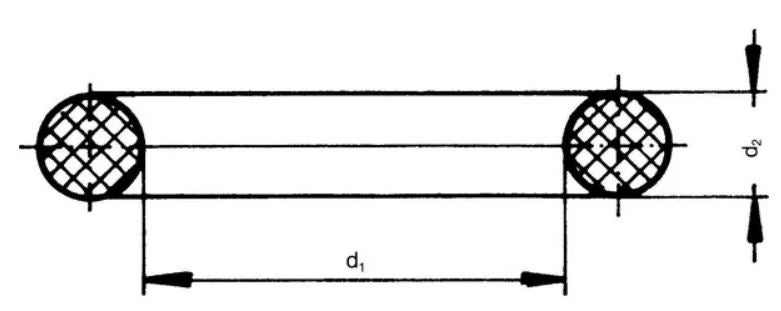

The right size for an o-ring is incredibly important. Using the wrong size of o-ring can result in leakage. The size of an o-ring is always specified as inner diameter x thread thickness (d1 x d2). These two dimensions are usually indicated in mm. The image below provides a good indication of how these two dimensions can easily be measured. There are various tools that can identify the size of an (existing) o-ring (for example, a measuring cone).

How is the size of the o-ring determined?

How is the size of the o-ring determined?To disassemble the o-rings, we have a handy hook tool set that makes it easy to remove an o-ring.

Choose the right material

The o-ring is available in various types of material. They are usually made of elastomers (elastic and rubbery plastics). The overview below explains the right use. When is what material most suitable and what is it (not) resistant to?

| Material | Temperature range | Resistant to | Not resistant to | Colour |

| NBR 70 | -30° to +110°C | Mineral oils and greases Abrasion Water up to 80°C Alcohol | Ageing Weather conditions Aromatic fuels Polar solvents Brake fluids | Black |

| FKM | -20° to +200°C | Weather conditions High temperatures Chemicals Mineral oils and greases Motor fuels Organic solvents | Hot water Water vapour Brake fluids Polar solvents Glycol-based brake fluids | Brown, green and black |

| EPDM | -45° to +130°C | Hot water Steam Ageing Chemicals | Mineral oils Aromatic fuels Concentrated acids | Black |

| Silicone | -55° to +200°C | High temperatures Weather conditions Ageing Various chemicals | Dynamic applications Solvents Fuels | Red |

| PTFE | -200° to +250°C | Various chemicals Friction Low and high temperatures | White | |

| CR rubber (Neoprene) | -35° to +110°C | UV radiation Weather conditions Ozone (Sea)water Refrigerant | Mineral oils Aromatics Oxygen-rich solvents | Black |

Good to know

Higher system pressures can cause deformation through the gap, known as extrusion, and this can result in seal failure. These failures can be avoided by choosing a harder sealing material or by installing support rings (backup rings).

As a rule of thumb, the following things can be taken into account.

- The o-ring can be used for static applications up to 50 bar. At higher pressures, the o-rings should be used in combination with backup rings.

- The o-ring can be used for dynamic applications up to 50 bar.

Support rings

Higher system pressures can cause deformation through the gap, known as extrusion, and this can result in seal failure. These failures can be avoided by choosing a harder sealing material or by installing support rings. Support rings are used in combination with both x-rings and o-rings for dynamic and static use.

Use support rings if one of the following situations occurs

- High pressure, usually from 50 bar;

- Large spaces between the parts to be sealed;

- High stroke speed or frequency;

- Rapidly changing pressure loads;

- High operating temperature;

- Major temperature swings;

- Many contaminants in the part to be sealed.

- If there are many contaminants in the part to be sealed, the support ring is installed not behind, but in front of the o-ring.

- Single-acting seals - the support ring is installed behind the seal, on the side facing away from the medium pressure.

- Double-acting seal - the support ring is installed both in front of and behind the seal.

- For the best result, always install the support rings on both sides.

Material

These support rings are mainly made of PTFE. This material is universally applicable and is known for its excellent sliding properties.

We hope that with our advice, we were able to help you make the right choice. Choosing the right seal can prevent defects. If you have any questions, please contact one of our product specialists or contact us via knowledgecenter@kramp.com.