Despite good maintenance, high-quality materials and innovative technology, there comes a time when a PTO shaft needs to be replaced. Replacing or choosing a PTO shaft involves various aspects. Read our advice on choosing the right PTO shaft here.

What is a PTO shaft?

PTO shafts are a connection from tractors to machines to then drive the machines. In addition to this application between vehicle and machine, PTO shafts may also be found on the machine itself. It serves as a flexible transmission where the driven shafts are not in line with one other.

How do you select the right PTO shaft?

When the old PTO shaft is broken or no longer functions properly, it will need to be replaced. In that case, there are two options: replace a part or fully replace the PTO shaft with a new one. Follow these steps in order to make the right choice.

Step 1: Find the brand and identify the cross journals on both ends

When replacing a part of or the entire PTO shaft, the first step is to identify the brand. The brand can easily be determined by looking for the brand logo on the guard. The brand logo may be illegible or the guard may no longer mounted to the PTO shaft. Is the brand not immediately recognisable or locatable? In that case, it is still possible to identify the PTO shaft in the web shop based on the dimensions of the cross journal.

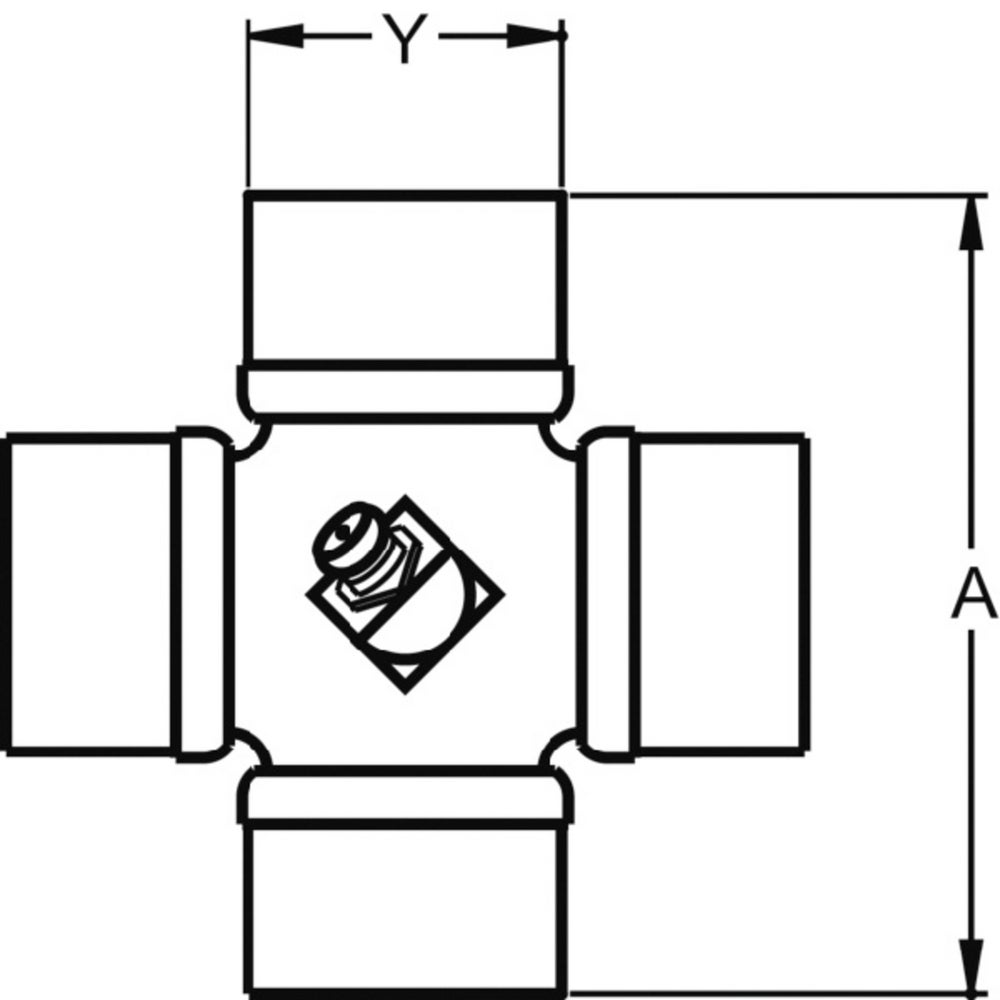

Measuring the cross journal

The best way to measure the cross journal is as follows: measure the a and y. Using this data and the information in the web shop or documentation, the size and type of the PTO shaft can be determined. The image below indicates how the cross journal can be measured.

Step 2: Identify whether it is a standard PTO shaft or if the shaft is fitted with accessories

The brand and type of shaft are determined in the first step. The second step involves looking at the type of clutch and the connection on the old PTO shaft. For instance, is it a standard PTO shaft or does it have a special clutch? This could be a friction clutch, shear bolt clutch or a overrun clutch. It is important to find the right clutch, because it usually has a machine-specific function. Sometimes, a combination of different safety systems in one clutch is also possible.

The image below shows the different types of clutch and their identification marks.

| Clutch type | Identification marks |

| Shear bolt clutch | Oval casing of housing and hub with one bolt that connects them. |

| Friction plate clutch | Round model with two or four friction plates. Fitted on one side with a disc spring or multiple compression springs. |

| Radial pin clutches and overrun clutches | Hard to identify on the outside because they often look identical. An overrun clutch can easily be twisted in one direction by hand. |

| Cam type cut out clutch | Larger and heavier in appearance than the radial pin clutch. |

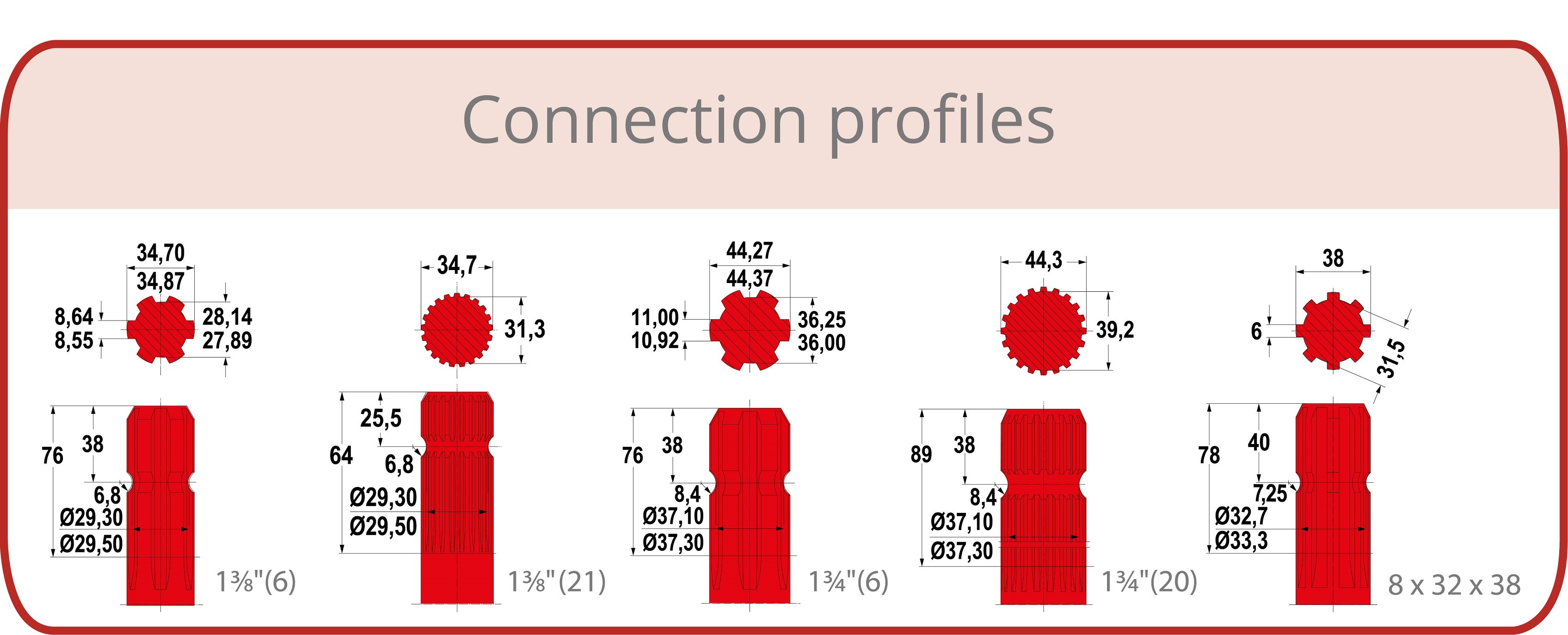

Step 3: Determine the connection

When determining the connection, it is important to look at two connection points, namely the one on the drive side and the one on the driven side. For example, the drive side is the tractor and the driven side is the machine.

Look at:

- the drive side, including 1 ⅜ 6 splines or 1 ¾ 6 splines.

- the driven side, including 1 ⅜ 6 splines or 1 ¾ 6 splines.

- and finally also determine the retention of the connections.

The different connections are shown in the image below.

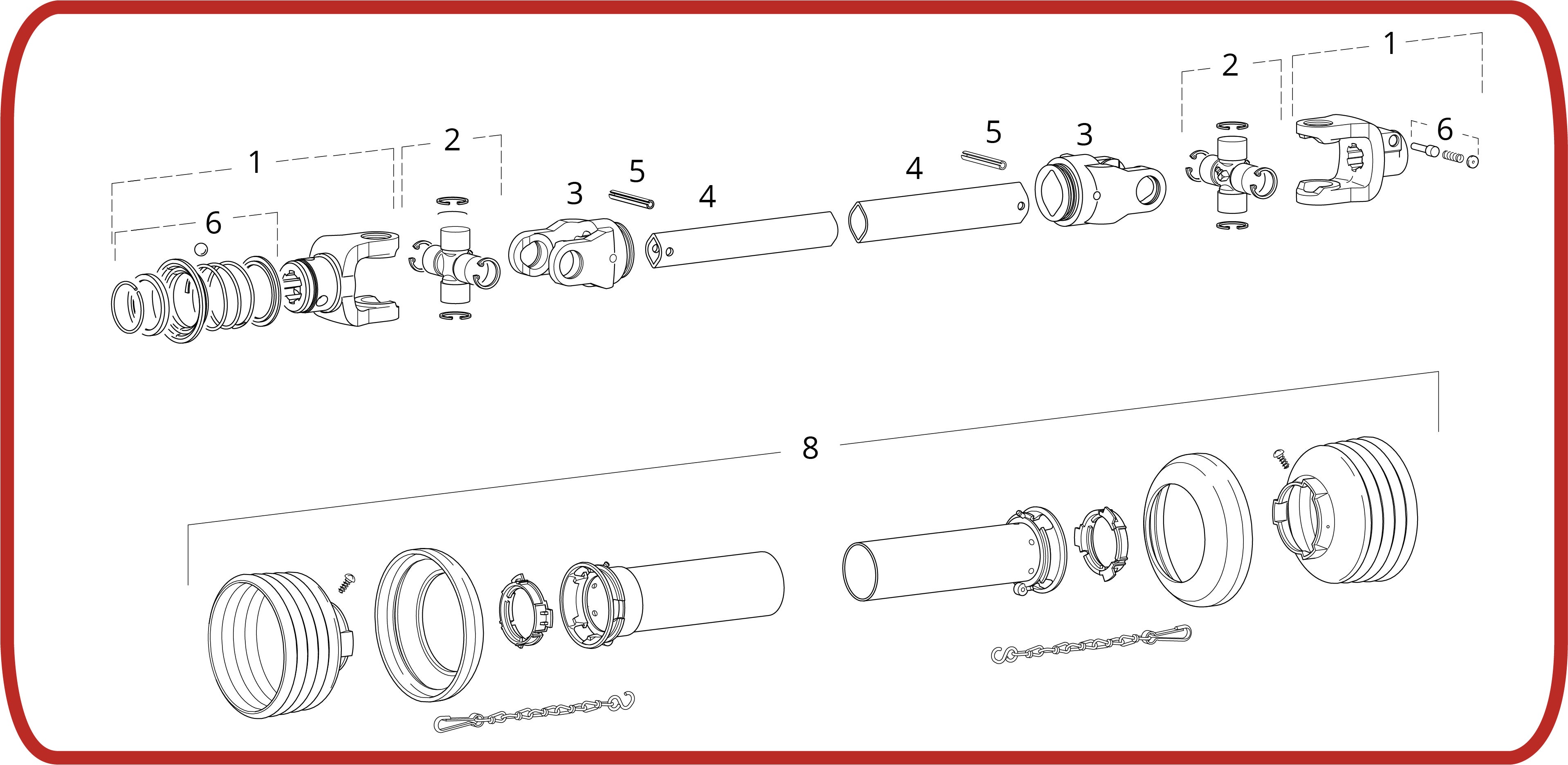

Step 4: Determine the length of the shaft

The length of the PTO shaft is normally determined by measuring the distance from the centre of the cross journal to the centre of the cross journal on the other end of the PTO shaft. Is this unknown or cannot be measured in this way? Please indicate the total length of the PTO shaft and our product specialists will be able to offer further assistance.

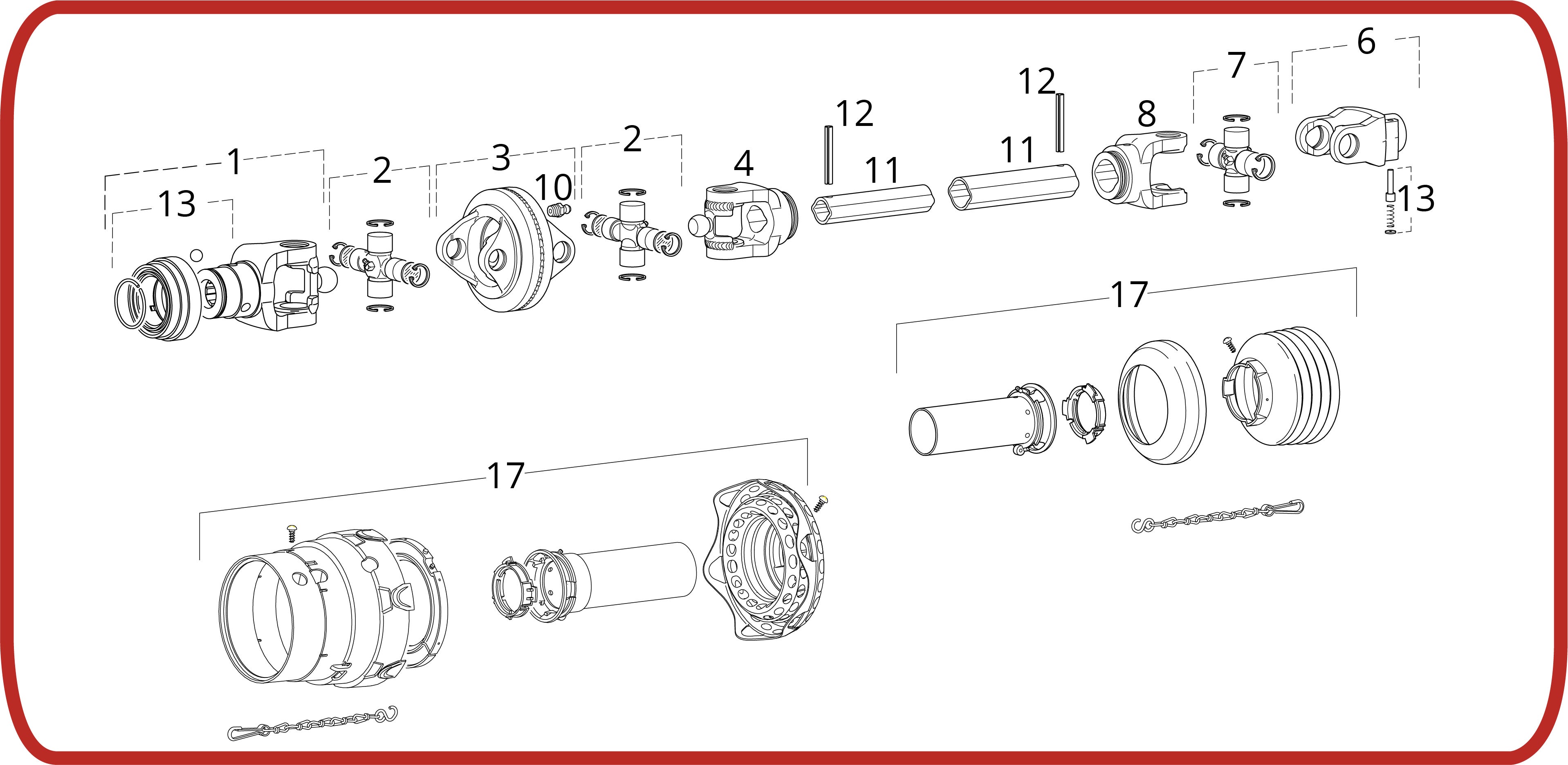

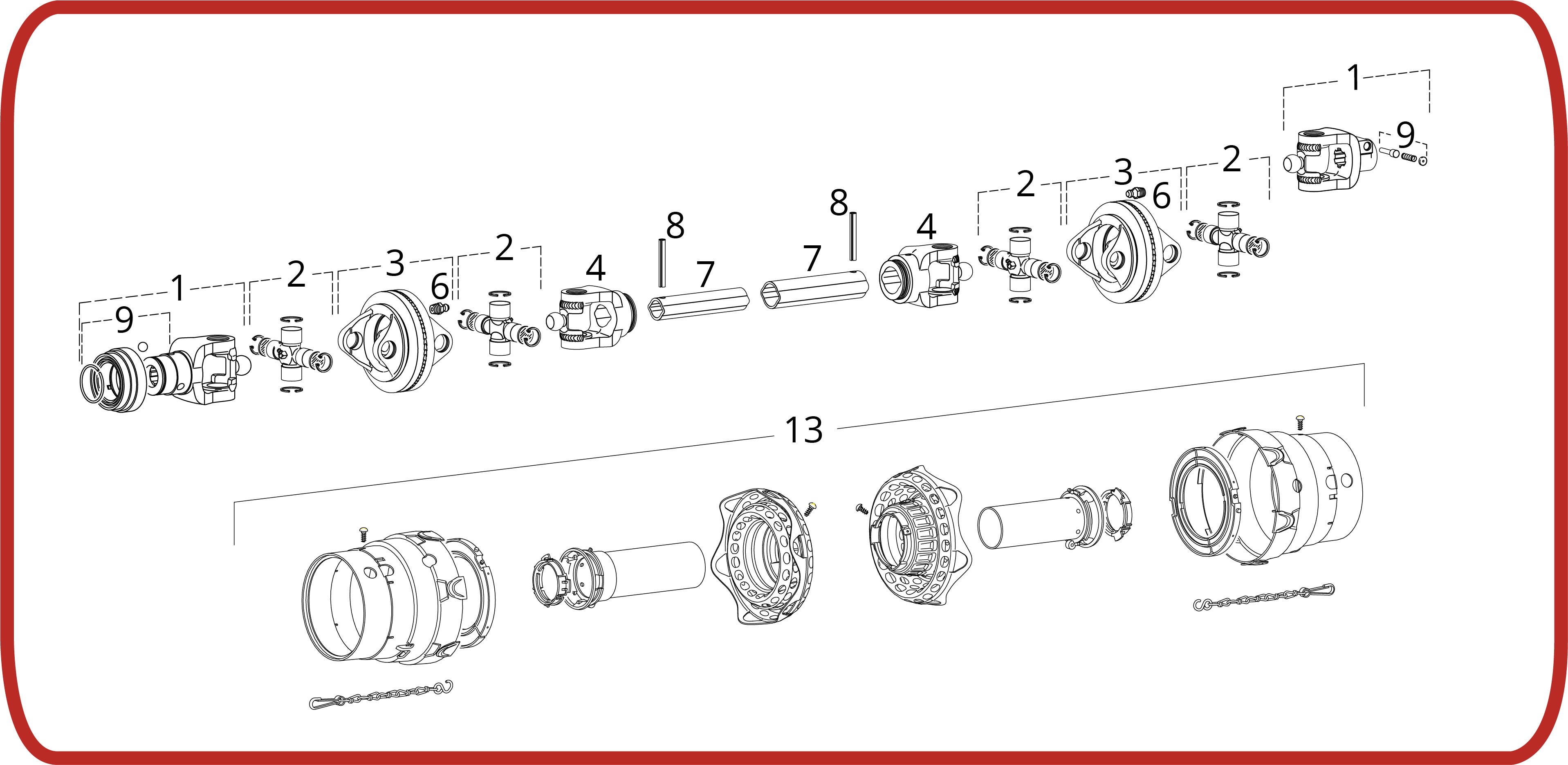

Below, a standard PTO shaft, a PTO shaft with a wide angle on one end and a PTO shaft with a wide angle on both ends are shown in a technical image. Accessories to the PTO shaft, such as a shear bolt or friction clutch, are usually mounted on the right side directly on the cross journal (number 1, usually machine side).

The standard PTO shaft

PTO shaft with a wide angle on one end

PTO shaft with a wide angle on both ends

Looking for a new PTO shaft, but no comparison material available?

Perhaps the above details are not yet known because a new PTO shaft needs to be selected? Then also include the steps below.

- Which machine is it? If it is a new machine and a new PTO shaft is required, then the manufacturer information is needed.

- What does the manufacturer prescribe? It is important here that the construction size is known.

- What is the function of the shaft? This is important information for determining whether a safety clutch is required. This safety clutch is normally used at the start of the driveline, so where the machine is connected to the tractor.

View our range of PTO shafts here or go to our product configurator to assemble a special PTO shaft. We hope that we were able to help you make the right choice with our advice. If you have any questions, please contact one of our product specialists or contact us via knowledgecenter@kramp.com.