When it comes to welding, protecting your eyes is crucial. Welding produces hazardous UV and IR radiation, intense visible light, and physical dangers like spatter and grinding particles. Common eye injuries, such as burns to the retina and cornea, can be easily prevented with the right protective equipment.

At Kramp, your safety is our priority. We've partnered with 3M to offer top-quality protective eyewear for welders. Our range of welding helmets and filters, featuring the latest 3M technology, ensures your eyes are well-protected, enhancing both safety and performance.

Understanding the Risks

Every year, over $300 million is spent in the US on costs related to workplace eye injuries, including medical expenses, workers' compensation, and lost production time1). Notably, more than 90% of serious eye injuries at work can be prevented with appropriate protective eyewear 2). Eye injuries are the most common injuries among welders, making up one-quarter of all welding-related injuries. This underscores the critical need for welders to use suitable protective equipment tailored to their specific tasks. Ensuring you have the right gear not only keeps you safe but also allows you to work more efficiently and confidently.

1) Source: www.osha.gov/SLTC/ eyefaceprotection (01.03.2017) 2)Source: www.preventblindness.org/ eye-safety-work (01.03.2017)

Controlling Exposure with Auto-Darkening Filters

Auto-darkening welding filters (ADF) provide a significant advantage over passive welding filters by allowing welders to keep their helmets in place more often. This constant visibility reduces the motivation to lift the shield frequently, leading to several key benefits:

- Reduced UV/IR Exposure: Keeping the helmet down minimizes the risk of exposure to harmful UV and IR radiation, whether from striking an arc accidentally or from the arcs of nearby welders.

- Lower Risk of Eye Injuries: With the helmet in place, there's less chance of foreign bodies like grinding swarf or weld spatter causing eye injuries.

- Neck and Hand Relief: The constant 'nodding' to flip the mask up and down is no longer necessary with an auto-darkening mask. This reduces neck strain and ensures your hands remain steady, keeping the electrode precisely where it should be at the critical start of the weld, leading to more accurate welds and less rework.

- Enhanced Productivity and Safety: Auto-darkening masks allow for eye and face protection to be worn before entering confined workspaces, making them particularly useful in challenging welding situations.

In addition to standard auto-darkening filters with a greenish tint, 3M offers advanced technologies to support welders. The 3M™ Speedglas™ Natural Colour Technology and 3M™ Speedglas™ Variable Colour Technology provide enhanced visibility and comfort, helping welders achieve better results with greater ease.

Natural Color Technology: Less Green, More Detail

Experience welding in a new light with 3M™ Speedglas™ Natural Color Technology. This innovative technology reduces the green tint commonly seen in conventional auto-darkening filters (ADFs), providing more contrast and natural-looking colors.

With 3M™ Speedglas™ Natural Color Technology, you can:

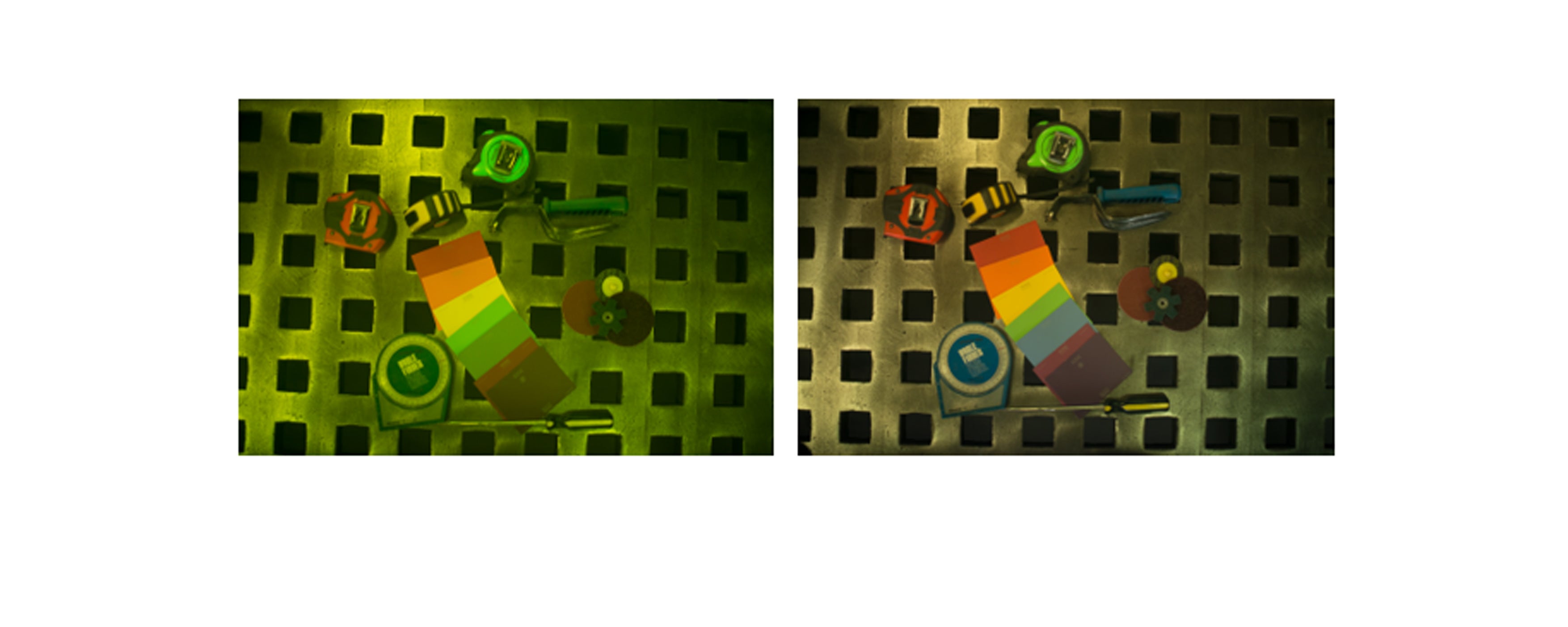

- See More Details: Enhanced clarity allows you to view your weld pool more accurately, helping you achieve more precise welds (see images below for visual difference).

- Improve Surface Reading: Better visibility of surfaces makes it easier to assess your work.

- Discern Colors Clearly: Easily distinguish colored machine controls and displays while looking through the filter.

Left: Sample competitor's filter shade 3, Right: Speedglas™ G5-01/03TW filter shade 3

Left: Sample competitor's filter shade 3, Right: Speedglas™ G5-01/03TW filter shade 3This technology offers a significant improvement in viewing your work and surroundings, making your welding tasks safer and more efficient.

Variable Colour Technology: Customizable Clarity for Optimal Welding

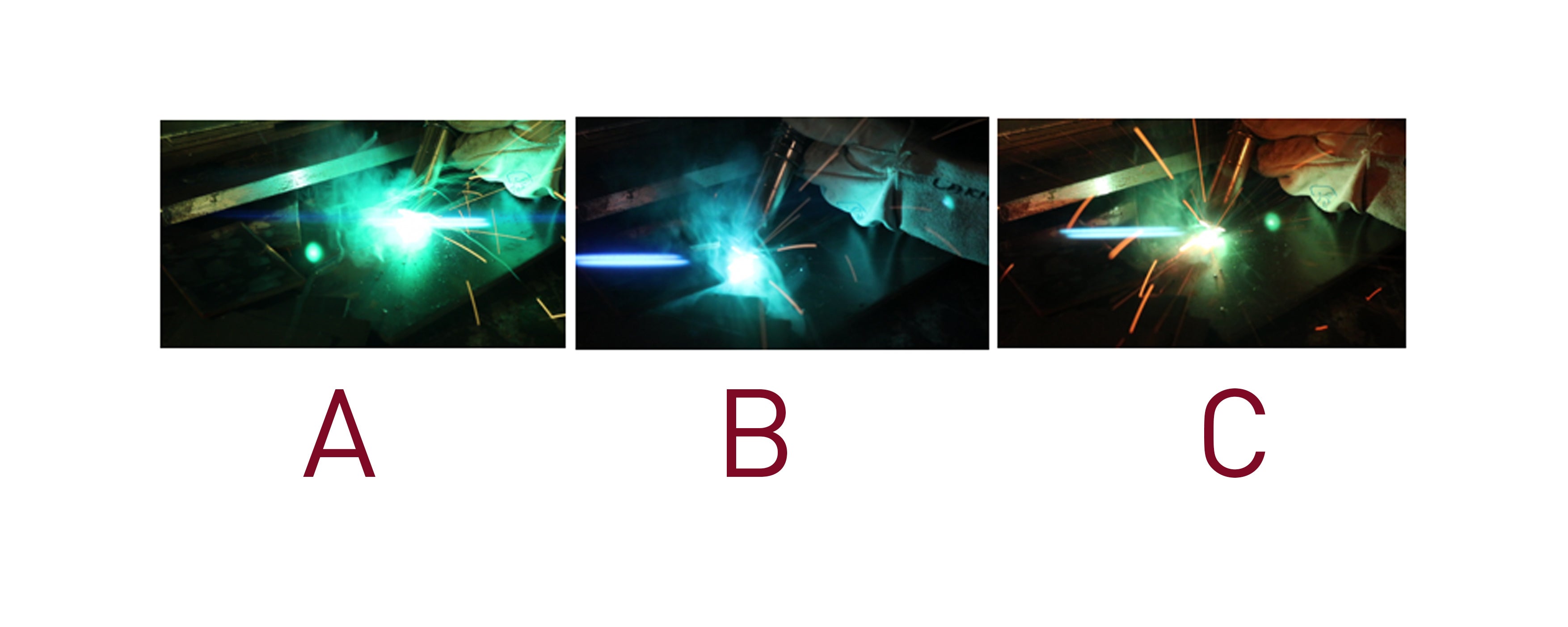

The 3M™ Speedglas™ Variable Colour Technology improves your view and control of the weld puddle by offering the choice between natural (A), cool (B), or warm (C) tones for your dark state.

Dark state 8 at variable colour level A, B and C.

Dark state 8 at variable colour level A, B and C.With 3M™ Speedglas™ Variable Colour Technology, you can:

- Select the Best Tone for Your Needs: Choose the color tone that provides the best viewing contrast for your welds and the most comfort for your eyes. Whether you prefer natural, cool, or warm tones, you have the flexibility to customize your view.

- Improve Weld Quality: By selecting the most comfortable and clear tone, you can better see the details of your weld puddle, leading to more precise and higher-quality welds.

- Enhance Eye Comfort: Different tones can reduce eye strain and increase comfort during long welding sessions.

This ADF not only offers the previously explained natural color view but also the option to choose between cooler or warmer tones, ensuring optimal visibility and comfort tailored to your personal preference.

Your Eyes Don't Have a Second Chance

Protecting your eyes while welding is not just a safety measure, but a critical practice to prevent serious injuries. Kramp is dedicated to protecting welders by offering advanced protective equipment featuring 3M™ Speedglas™ Natural Colour Technology and Variable Colour Technology. These innovations help significantly reduce the risk of UV/IR radiation exposure and physical eye hazards. Investing in the right gear not only enhances safety but also improves work quality and efficiency. Remember, your eyes don’t get a second chance—ensure they are protected with the best technology available, supported by Kramp's commitment to your safety.

Share this Article

Let’s collaborate in sharing this article across communication channels, including your website, newsletters, and social media platforms, to enhance customer experience and highlight the value of our products and services. By working together, we can empower professionals with the tools they need to maximize productivity, reduce operational costs, and excel in a competitive industry, further strengthening our commitment to delivering exceptional value to our clients.

Any Questions?

Our team is here to provide expert guidance, answer any questions, and assist in selecting the most suitable welding helmet for your customers' requirements. Feel free to reach out to our product specialists or send an email to the Knowledge Center for further assistance. If you don't have a Kramp account and are looking for products mentioned in this article, find a dealer near you.