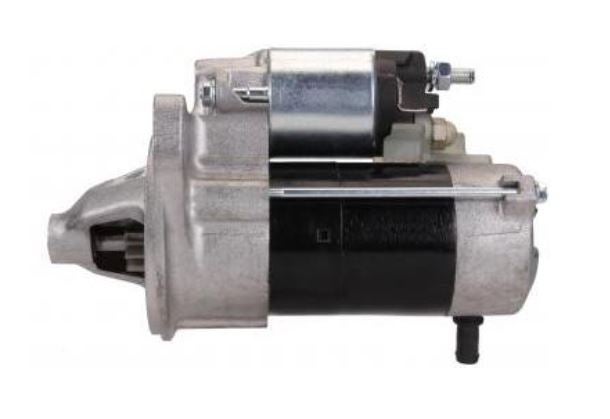

A machine or tractor is useless without a working engine. To kick the engine into motion, you need a working starter motor. A poorly performing starter motor is bound to create problems. It can cause the engine not to start or damage the flywheel. That’s why it’s important that you choose the right starter motor and maintain it properly. What else should you be looking out for and how do you recognise and prevent potential issues? Read on to find out more.

What is a starter motor or starter?

A starter motor – also known as a starter – is an electric motor that cranks an internal combustion engine to start up the engine under its own power.

When current from the vehicle’s battery is applied to the starter’s solenoid or relay (an electrically wound component made of insulated copper wire), usually via an ignition switch, the actuator (bendix) is pushed out onto the starter’s drive shaft, which engages the engine’s flywheel. At that point, the circuit between the solenoid’s main contacts is closed. The electric motor starts rotating, allowing the engine to start.

Different types of starter motors

We have listed five types of starters with a short description for you below:

DD starter (Direct Drive): the direct drive starter motor is the most common type of starter motor. This is a solenoid-operated unit that is used in multiple applications and designs.

DD starter (Direct Drive)

DD starter (Direct Drive)PLGR starter (Planetary Gear): planetary gear starter motors are gaining traction. They’re rapidly replacing DD starters.

PLGR starter (Planetary Gear)

PLGR starter (Planetary Gear)PMGR starter (Permanent Magnet Gear Reduction): the permanent magnet gear reduction starter is relatively light. Its design is fairly simple and it generates less heat than other starters when in operation.

PMGR starter (Permanent Magnet Gear Reduction)

PMGR starter (Permanent Magnet Gear Reduction)PMDD starter (Permanent Magnet Direct Drive): the permanent magnet direct drive starter is similar to the DD starter in many ways. The main difference is that it has permanent magnets rather than field coils.

PMDD starter (Permanent Magnet Direct Drive)

PMDD starter (Permanent Magnet Direct Drive)OSGR starter (Off-Set Gear Reduction): the off-set gear reduction starter is designed to work under high speed and low current. It’s relatively light and compact, making it easy to install. This makes the OSGR starter a popular option for vehicles.

OSGR starter (Off-Set Gear Reduction)

OSGR starter (Off-Set Gear Reduction)

Most common problems

The immobiliser is a crucial part of an engine. Poor maintenance or daily wear and tear can cause a starter motor to become faulty over time. We have summed up the most common signs of a poorly performing or failing starter for you below.

1. Battery

The starter system has been activated, the dashboard shows that your lights are on and should work, but the engine doesn’t start. The problem is probably due to a weak battery. It takes a lot of battery power to crank the engine. You can try starting the tractor or machine using jumper cables or a starter kit. Starting a vehicle can be more difficult during the winter months when the engine is cold.

2. Grinding noise

When the starter’s drive sprocket is worn or not engaging properly, it will make a grinding noise, much like the noise you hear when you accidentally press the ignition switch while the engine is already running. You should have the vehicle serviced. If you ignore the grinding noise, there may be damage to the flywheel ring gear.

3. Freewheeling

Freewheeling occurs when you try to start the engine and hear a whining noise without the engine starting. This means that the starter isn’t engaging with the flywheel. The noise could also point to a failing starter motor clutch (bendix). You should have your vehicle serviced as soon as possible. If you don’t, the whole unit may have to be replaced.

4. Clicking sound

If your tractor or machine won’t start on the first try, but the engine does come on after you’ve pressed the ignition switch again, the problem is probably due to the solenoid. This part either transmits the full electrical current to the starter or nothing at all. A damaged solenoid will sometimes cause the starter to make a clicking sound when you turn the key. The problem might also be due to a weak or a dead battery.

5. Starter motor stays on after engine is engaged

When you start the engine and release the key, the current to the starter motor should be cut off. If the starter motor keeps running after the engine has ignited, the main contacts in the solenoid circuit have most likely fused together in the closed position or the vehicle’s ignition switch is stuck. If this problem is not remedied immediately, the relay (electric switch) will be stuck in the ‘on’ position. This will eventually lead to major damage to the starting system as a whole and the engine flywheel. To prevent this, you need to have your vehicle serviced right away.

The table below lists a number of problems that can occur with a starter and offers suggestions for how to solve them:

| Problem | Possible cause | Solutions |

| Engine won’t start |

|

|

Engine won’t start Engine turns too slowly

|

|

|

| Starter keeps running |

|

|

| Starter turns, but engine won’t start |

|

|

| Starter doesn’t engage/disengage properly |

|

|

Any questions?

Please do not hesitate to reach out to a Kramp product specialist or find a Kramp dealer in your area if you have any questions about starters or want to know which starter would be the best fit for you. You can also contact us directly by sending an email to knowledgecenter@kramp.com. To find out more about the starters and other motor parts in our product offering, we invite you to visit our webshop.